Whirling technology

We manufacture and deliver whirling devices for your production tailored to your products.

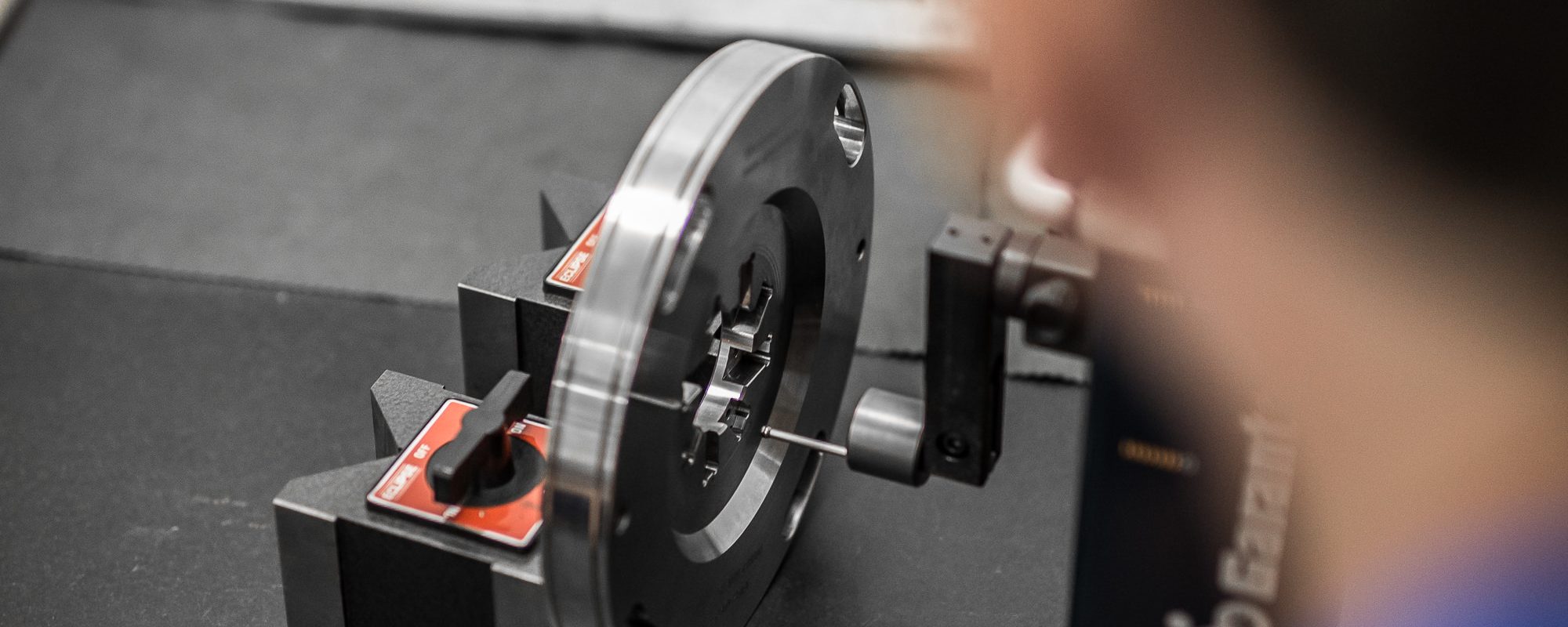

With the whirling process, geometries can be produced in a spiral and that in one pass. The advantage of the whirling process is that the heat is dissipated through the chip and only short chips are produced during the process.

We deliver for the whirling technology:

- Vortice rings and whirling tools for L3, L4 and other whirling units

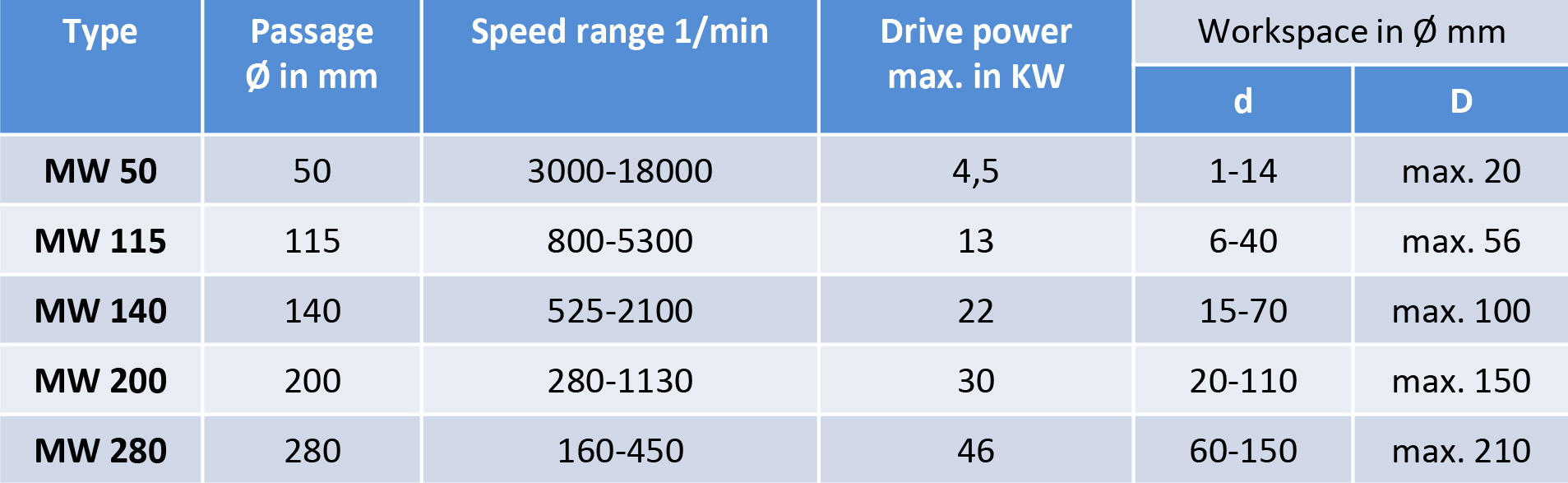

- Whirling aggregates and whirling units as standard and as special equipment

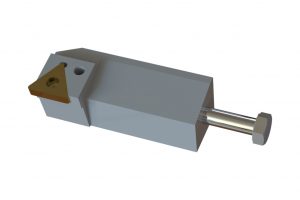

- Adjustment tools

- Tool holders

- Centering vises

- Complete whirling machines

Download

For dimensions and performance data, please refer to the data sheet.

DE

DE